Custom Flexible Packaging Services

Huiyang Packaging offers a full range of custom flexible packaging and film customization services, customizing thickness, material, size, printing, and other characteristics according to customers’ needs. Whether it’s bolsas para envasado de alimentos, bolsas para envasado diario de productos químicos, film packaging, or other industries’ packaging needs, we can provide the best solutions for our customers.

Our customization services are designed to provide our customers with quality, innovative, and personalized packaging products that help them stand out in the marketplace.

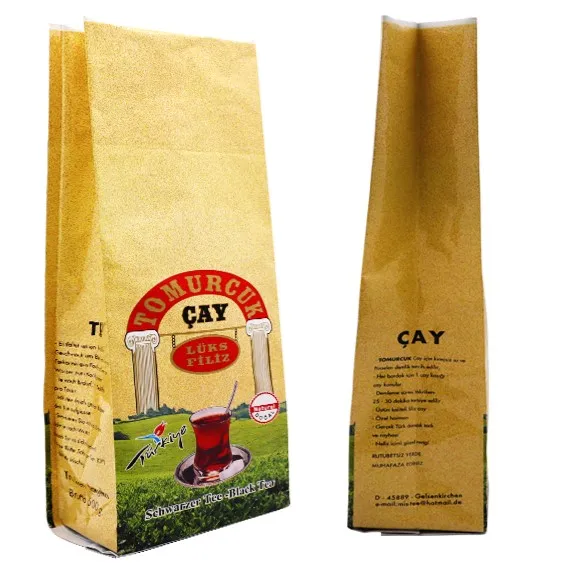

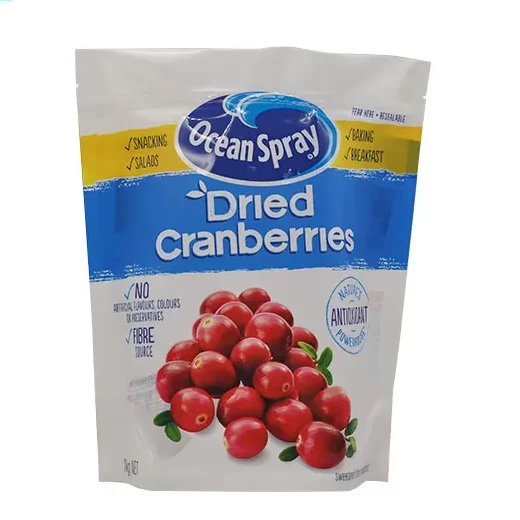

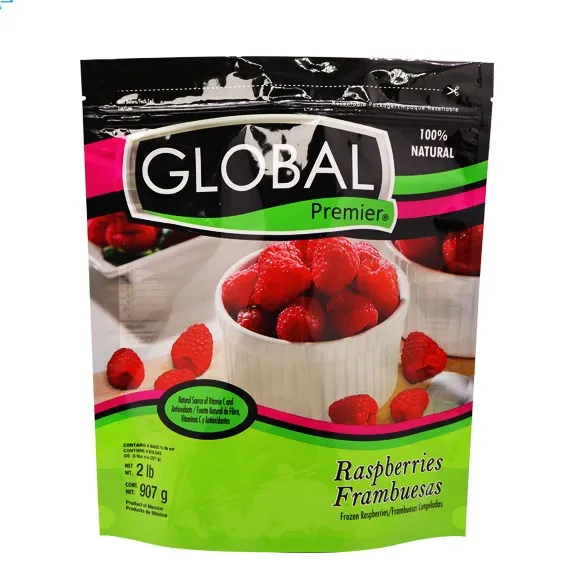

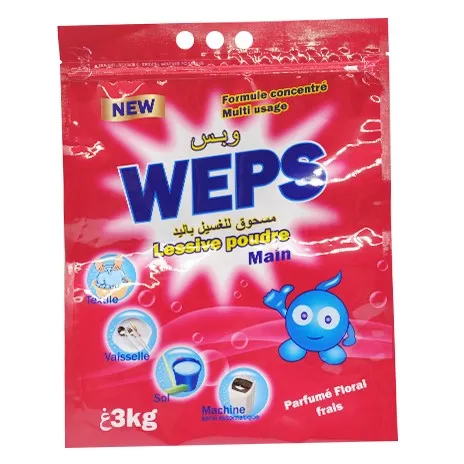

Custom Flexible Packaging Film Product Case

We have crafted personalized flexible packaging films that are designed to highlight our customers’ brand image and product features. These custom flexible packaging feature unique designs and colors to provide customers with distinctive packaging solutions.

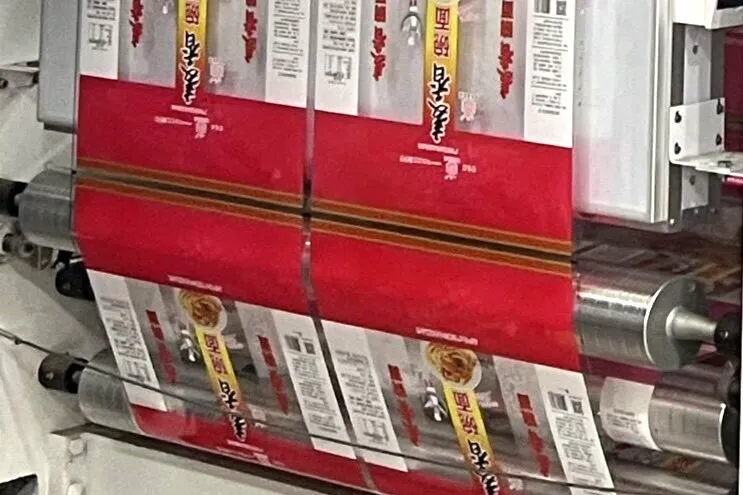

Advanced Printing Equipment and Mature Printing Technology

Adopting advanced printing equipment and processes to provide higher printing accuracy and printing speed, we can achieve up to 10 colors of printing, providing products with a wealth of color choices and surface treatment effects, to meet the needs of different products and brands of personalized envases flexibles personalizados.

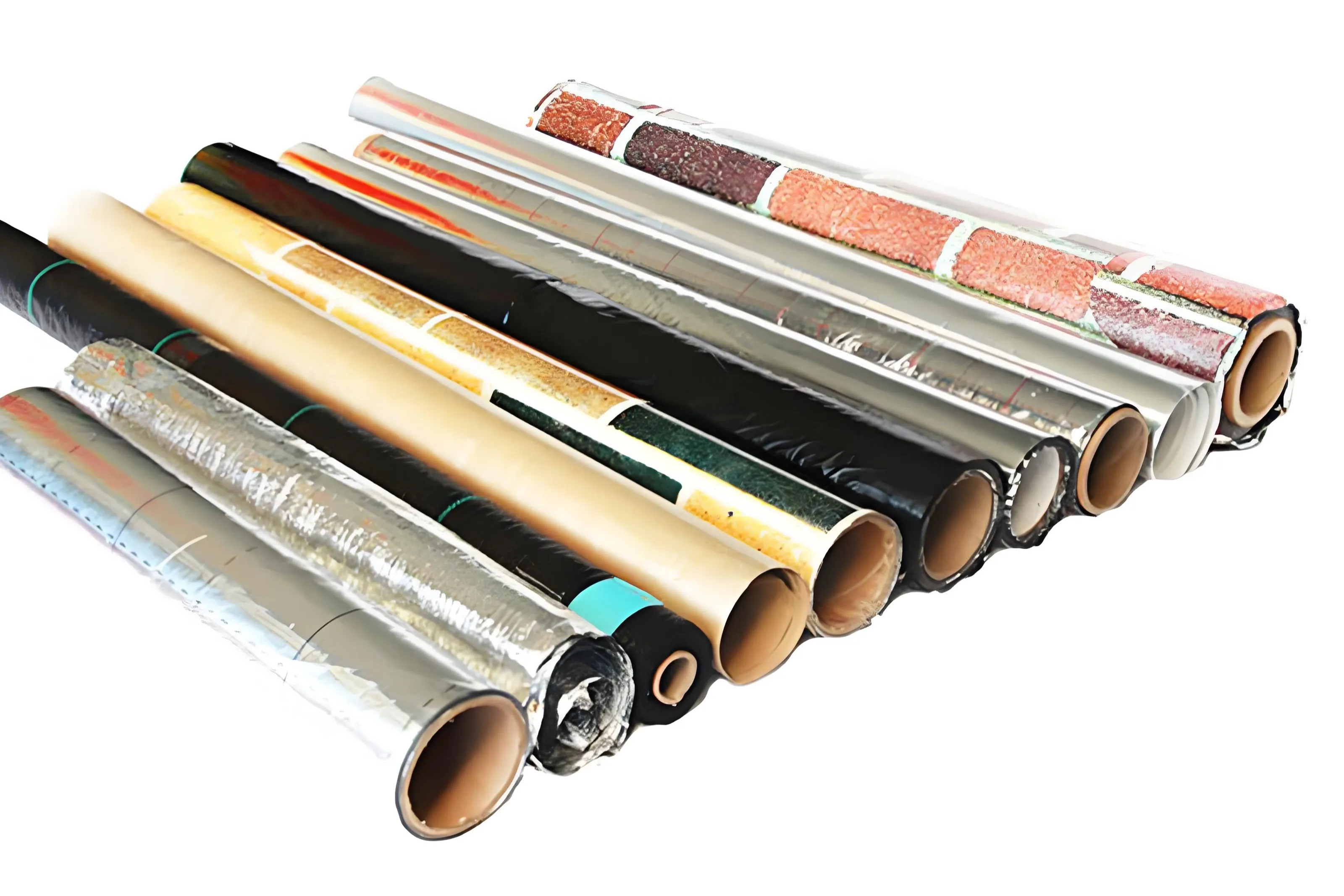

Analyzing the Raw Materials for Custom Flexible Packaging Films

The common raw materials of flexible packaging film include PE film, PET film, BOPP film, VMPET(aluminized polyester film) film, AL (aluminum-platinum) film, VMCPP film, CPP film and other materials. With good flexibility, transparency and durability, it is widely used in food, daily chemical supplies, medical supplies and other fields of packaging. There are also environmentally friendly materials to choose from, such as biodegradable plastics and recyclable plastics. These environmentally friendly materials have passed certification certificates, such as EN13432, ASTM D6400, etc., and have been widely recognized in terms of sustainable development and environmental protection.

Custom Flexible Packaging Bag Sorting for All Industries

Our custom flexible packaging solutions cater to all industries, providing tailored bag sorting services to meet diverse needs.

Bolsa Stand Up

Zipper Pouch

K-Seal Stand Up Pouch

Quad Seal Pouch

Spouted Pouch

3 Sides Seal

3 Sides Seal Pouch

Shaped Pouch

Fin/Lap Seal pouch-Front

Fin/Lap Seal with Side Gusseted Pouch-Front

Lidding Film

Shrink Sleeve/Labl

Roll Stock

Fin/Lap Seal pouch-Back

Fin/Lap Seal with Side Gusseted Pouch-Back

Cómo elegir la bolsa de embalaje flexible adecuada a sus necesidades

Huiyang Packaging offers a range of custom flexible packaging features, such as zippers, hanging holes, tear-offs, and spouts, as well as a variety of surface treatment options and specialized material choices, to meet the needs of different products and to enhance the utility of the packaging and the brand image.

Cremallera

El diseño de la cremallera, fácil de abrir, mejora el sellado y resellado del envase.

Agujero para colgar

Diseño con orificios para colgar que permite exponer cómodamente el producto y mejorar su imagen.

Lágrima Hotch

Diseño "tear hotch" para una apertura rápida y un fácil acceso al producto.

Caño

Diseño de caño profesional para productos líquidos y granulados, que garantiza la facilidad de uso y la ausencia de fugas.

Ventana transparente

El diseño transparente del escaparate permite a los consumidores visualizar las características del producto y aumentar la confianza en las decisiones de compra.

Forma personalizada

Formas personalizadas para crear una imagen de envase única según las características del producto y la demanda del mercado.

Alta barrera al vapor

El diseño de barrera contra la humedad de alta eficacia protege los productos de la humedad y prolonga su vida útil.

Opciones de tratamiento de superficies

Diversas opciones de tratamiento de la superficie, como mate, suave al tacto y brillante. Proporciona un aspecto de envase personalizado.

Película

Opciones de materiales especializados, como alta barrera, alta temperatura, resistencia a la perforación y al desgarro.

Varios tamaños

Hay disponibles varios tamaños para satisfacer las diferentes especificaciones de los productos y las necesidades de envasado, lo que mejora la aplicabilidad y la flexibilidad del envasado.

Opciones de fondo de bolsa/fuelle

Diseños de fondo de bolsa, cuatro soldaduras o tres soldaduras laterales para adaptarse a diversos formatos de producto.

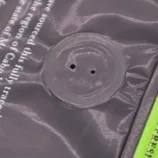

Agujero de respiración

El diseño del orificio de respiración garantiza la circulación del aire en el interior del envase para mantener la frescura del producto.

Steps to Personalize Your Custom Flexible Packaging Solution

Demand Analysis and Communication

First of all, fully communicate with you to understand the product characteristics, brand image, market positioning and specific needs for packaging. This includes understanding the functional requirements of the packaging, design style, material selection, etc.

Design and Proposal

Design an exclusive packaging solution according to your needs and requirements. This may involve discussions on packaging design, material selection, printing effects, etc. The design team will usually provide multiple options for the client to choose from, and modify and adjust them based on your feedback until they achieve satisfactory results.

Sample Preparation and Validation

Once the design is determined, a sample is produced for your confirmation. Samples can be used to assess whether the appearance, texture, function and other aspects of the package meet its needs. If necessary, multiple sample confirmations can be performed until final satisfaction is achieved.

Mass Production and Delivery

After sample confirmation, mass production begins. The production team selects the right production process and equipment according to your order requirements to ensure the timely delivery of high-quality customized packaging products.

Still have questions?Tell us your concerns and let a team of professionals help you out!

Optimized Custom Flexible Packaging Cases

1. Preliminary demand communication and quality inspection investigation

We met an American customer at the Canton Fair who came to us with a chicken bag for inquiry. During the initial contact, we learned more about the quality problems with bags produced by their previous supplier, and the customer had to find a new supplier. Through communication with our customers, we have a detailed understanding of their packaging needs, including material structure, thickness, bag type and size. At the same time, we take the bag back to the quality inspection department for material and thickness testing to ensure that we provide an accurate quote to the customer.

2. Design improvement and durability test

Based on the results of the initial requirements communication, our design team set out to redesign the handle part of the bag and provide a variety of design options for the customer to choose from. After the customer’s confirmation, we transferred the design to production and carried out several durability tests. However, the results were not ideal and we are aware that further improvements are needed.

3. Function optimization and material upgrade

Our research and development team stepped in again to further optimize the handle part of the bag. After repeated communication and testing with the customer, we decided to adjust the material structure of the inner and outer layers of the bag to improve the use experience. At the same time, according to the requirements of customers, we have replaced recyclable grade environmental protection materials to improve the environmental performance of products.

4. Final delivery and customer satisfaction

After many improvements and tests, we finally succeeded in providing high quality packaging solutions that meet the needs of our customers. We delivered the final product to our customers and received their high recognition and satisfaction. While ensuring product quality and delivery time, we always take the needs of customers as our direction and driving force, and constantly pursue product innovation and optimization.

Póngase en contacto con nosotros

Comparta sus necesidades y póngase en contacto con nuestro experimentado fabricante de envases flexibles. Rellene el formulario para obtener soluciones de envasado flexible personalizadas que mejoren su marca. Póngase en contacto con Huiyang Packaging hoy mismo.