Huiyang Ambalaj'dauluslararası evcil hayvan maması markaları için OEM üretiminin ön saflarında yıllar geçirdik ve on binlerce yüksek sıcaklıkta imbik torbaları günlük. Gerçek zorlukları gördük: 121°C sterilizasyon sırasında patlayan alüminyum folyo torbalar ve reddedilen ve yeniden yapılan çevre dostu malzemeler. Bunlar ders kitabı teorileri değil, üretim alanından zor kazanılmış dersler. Özel imbik poşet üreticisi olarakMalzeme seçiminin ısı direnci, maliyet verimliliği ve ürün güvenliği arasında kritik bir denge olduğunu biliyoruz. Deneyimlerimiz, her seferinde güvenilir, üretime hazır ambalajlar elde etmenizi sağlar.

Yüksek Sıcaklık Retort Torbalarının "cehennem testi": Hangi malzemeler 121°C'ye dayanabilir?

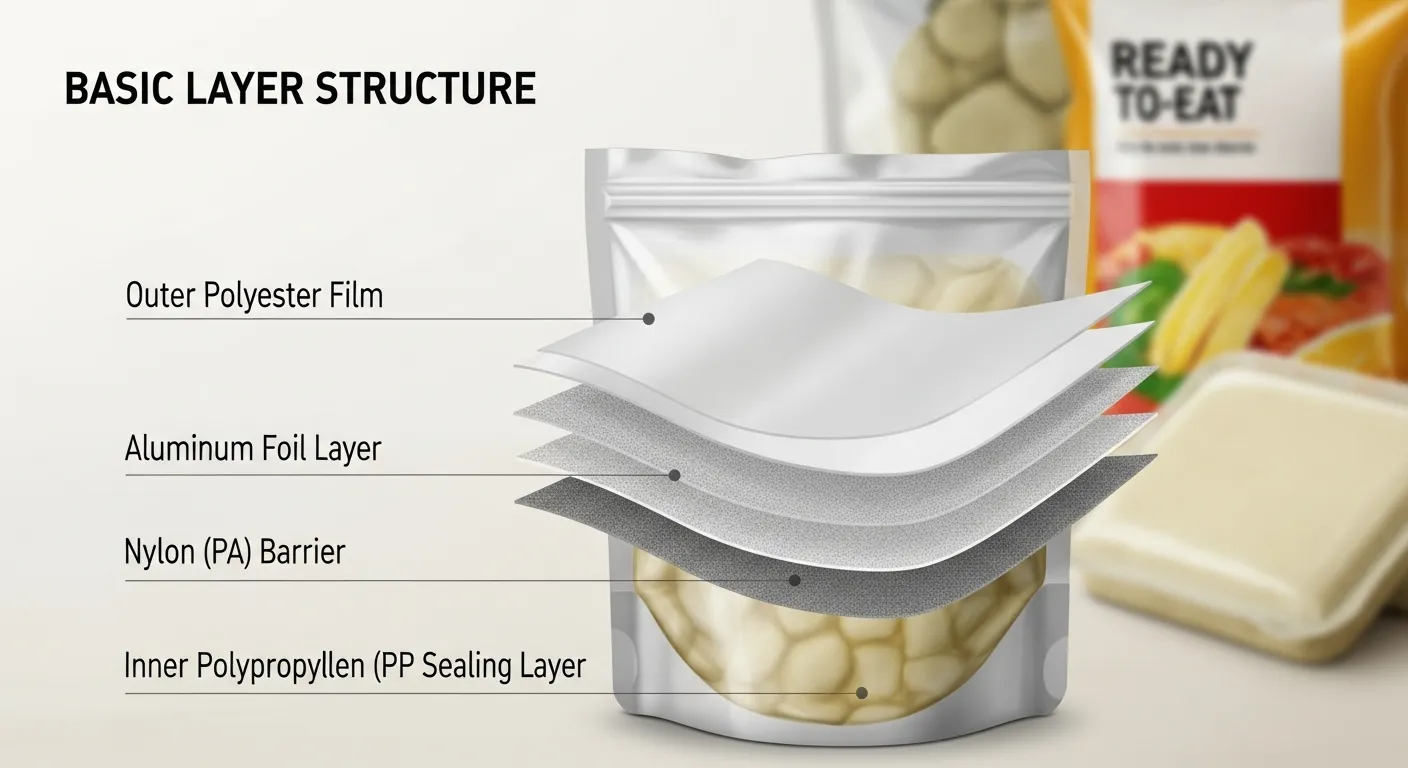

Temel dört katmanlı yapı (endüstri standardı)

Bir paket hazır körinin ambalajını açtığınızda, bu "istiflenmiş tırnak akışını" göreceksiniz:

Dış katman: 12μm PET film

- Fonksiyon: çizilmeye dayanıklı, delinmeye dayanıklı ve logo solmaz.

- Sır: Bir marka bir keresinde tasarruf etmek için BOPP'ye geçti, ancak basılı desen imbikten geçirildikten sonra soyut bir tabloya dönüştü ve 800.000 yuan kaybetti.

İkincil katman: 15μm naylon (PA)

- İşlev: darbe direnci + oksijen penetrasyonunu önleme, ambalajın "bağına" eşdeğer.

- Devrilme vakası: Belirli bir OEM fabrikası yanlışlıkla gerilmemiş PA kullanmış ve 121°C'de pişirildikten sonra büzülme oranı 5%'yi aşmış ve torba lahana turşusuna dönüşmüştür.

Çekirdek: 7μm alüminyum folyo

- İşlevi: hayat kurtaran bir çekirdek olan oksijen, ışık ve su buharını bloke eder.

- Acı nokta: Alüminyum tabakanın iğne deliği oranı 3/㎡'den az olmalıdır (test sırasında yüksek voltajlı elektrik kıvılcımları kullanılır ve delikler varsa mavi ışık yayılır).

İç katman: 70μm CPP (dökme polipropilen)

- İşlev: gıda ile doğrudan temas, ısı yalıtımı en üst düzeye çıkarılmalıdır.

- Kan ve gözyaşı geçmişi: Bir parti CPP ısıya yeterince dayanıklı değil ve torba piştikten sonra plastik kokuyor. Geri çağırma maliyeti bir süit satın almak için yeterli.

İleri Seviye Oyuncular

- Alüminyum folyo yokAlüminyum folyo yerine EVOH (etilen-vinil alkol kopolimeri) kullanır ve oksijen geçirgenliği 3cc/㎡-gün'den azdır. Japon Nichirei'nin düşük sıcaklıkta pişirme torbaları bu hileyi kullanır, ancak maliyeti alüminyum folyodan 40% daha pahalıdır.

- Zenginlere özel: 150°C'ye dayanıklı ve mikrodalgada kullanılabilen havacılık sınıfı silikon oksit (SiOx) film. Amerikan retort poşet (yüksek sıcaklıkta retort dik duran torba) markası Packit bununla askeri siparişler kazandı, ancak metrekare fiyatı iki kilo biftek almaya yetiyor.

2. Ölümcül Detaylar: Retort Torbalarının "100°C Sıcaklık Farkı Yaşam ve Ölüm Çizgisi"

1. Sıcaklık haini: ısı yalıtımı

Sızdırmazlık mukavemeti ≥50N/15mm sektörün kırmızı çizgisidir. Ancak burada şeytani bir ayrıntı var:

- Soğuk mühür VS ısıl mühür:

Soğuk yapıştırıcı (Japonya'daki Toyo Can'dan Toyo-Lac gibi) 135°C'de >90% mukavemet tutma oranına sahiptir, ancak üretim hattı hızının 30%'ye kadar yavaşlatılması gerekir.

Geleneksel ısı yalıtım katmanı (CPP) düşük maliyetlidir, ancak sıcaklık farkı biraz büyükse delaminasyona uğrayabilir. Bir döküm fabrikasında buhar basıncındaki 2 psi'lik dalgalanma nedeniyle bir parti mal delaminasyona uğramış ve hurdaya çıkmıştır.

2. Görünmez katil: artık çözücü

Baskı mürekkebinin solvent kalıntısı <5mg/㎡ olmalıdır (ulusal standart GB 9685). Belirli bir çevrimiçi ünlü balık turşusu önceden hazırlanmış gıda markası iptal edildi:

- Muhteşem baskı arayışında, mürekkep tabakasının kalınlığı standardı aştı → pişirme sırasında çözücü buharlaştı ve genleşti → alüminyum folyoda mikro gözenekler ortaya çıktı → raf ömrü boyunca torba genleşme oranı 17% idi;

- Satış sonrası maliyet, yeni bir üretim hattı kurmaya yeter, kanlı bir kayıp!

3. Nesiller tarafından zorlanan "talep"

- Mikrodalgaya uygun + şeffaf: dış katmanın 140°C'ye dayanıklı ve şeffaf olması gerekmektedir. Alman KHS şirketi PET/PA/EVOH/PP'den oluşan dört katmanlı şeffaf bir pişirme torbası piyasaya sürdü, ancak oksijen geçirgenliği alüminyum folyo torbalardan 10 kat daha yüksek ve sadece kısa raf ürünü olarak kullanılabiliyor.

- Çevre koruma kişiliği: Avrupalı bir evcil hayvan maması markası kağıt-alüminyum kompozit torbalar kullanıyor ve bunların geri dönüştürülebilir olduğunu iddia ediyor. Geri dönüşüm tesisi doğrudan kağıt + alüminyum + plastiği kabul etmeyi reddediyor - bu yeşil yıkama dalgası iyi oynanıyor.

2025'te Kopuş: Oyunun Kurallarını Kim Yeniden Yazıyor?

1. Politika nükleer bombası: alüminyum folyonun küresel kuşatması

- AB, 2025 yılından itibaren alüminyum içeren kompozit ambalajlara 800 €/ton ekolojik vergi uygulayacak.

- Japonya Ambalaj Derneği "yarı alüminyum kullanım planını" güçlü bir şekilde desteklemektedir: alüminyum folyonun bir kısmını değiştirmek için alüminize PET (VMPET) kullanmak, ancak oksijen bariyer özelliği 30% kadar azalır ve raf ömrü kısalmaya zorlanır.

2. Malzeme Devrimi: Nano kaplamanın karşı atağı

- Seramik kaplama: Japon Otsuka Packaging'in 150°C'ye dayanıklı ve mikrodalgada pişirilebilen AlOx kaplaması (alüminyum oksit) bebek maması poşetlerinde kullanılmaya başlanmıştır;

- Grafen takviye katmanı: Çinli bir araştırma enstitüsü, delinme direnci 200% kadar artırılmış numuneleri deneme amaçlı üretti, ancak ton başına maliyet bir BYD satın almak için yeterli.

3. Siyah işlem teknolojisi: 8 saatten 8 dakikaya

- Ultra yüksek sıcaklıkta anında sterilizasyon (UHT): 135℃/3 saniye flaş sterilizasyon, yüksek bariyerli alüminyum kaplamalı torbalar ile raf ömrü 18 aydan 6 aya uzatılır, ancak lezzet kaybı oranı 5%'den azdır (geleneksel buharlama kaybı 15%'dir);

- Lazer mühürleme: ısıyla yapıştırma şeritlerinin yerini alır, doğruluk ± 0,1 mm, özel şekilli torbalar (kendinden ayaklı nozullu torbalar gibi) için uygundur, ancak ekipman yatırımı küçük bir şehirde bir ev satın almak için yeterlidir.

Üreticiler için Hayatta Kalma Rehberi

- Düşük uç hacimli tip: ilçe pazarına odaklanan dört katmanlı alüminyum folyo torba + geleneksel buharlama işlemi;

- Orta seviye yükseltme: VMPET, 50% alüminyum folyo + UHT sterilizasyonun yerini alır ve birinci ve ikinci kademe şehir süpermarketlerini hedefler;

- Üst düzey premium tip: alüminyum içermeyen EVOH şeffaf torba + lazer mühürleme + karbon ayak izi etiketi, teknoloji hissi ile ürünün üst düzey hissini vurguluyor.

(Lütfen bize pazar konumunuzu, büyüklüğünüzü ve miktarınızı söyleyin ve size özel bir fiyat teklifi sunalım)

Buhar Torbasındaki Endüstrinin İçini Görün

Bir marketten bir paket hazır köri aldığınızda gördüğünüz ambalaj fiyatlarındaki farkın arkasında malzeme bilimcilerin, politika yapıcıların ve maliyet muhasebecilerinin on yıllık mücadelesi vardır. Bir dahaki sefere poşeti yırtıp açtığınızda bir düşünün: Bu film, yemeğinizi güvenli bir şekilde ağzınıza ulaştırmadan önce kaç derece ölüm kalım mücadelesi vermiştir.

Etkileşim: Çevre dostu ambalajın gıda fiyatlarını 30% artıracağını, ancak ayda 3 metrekare toprağı daha az kirleteceğini biliyorsanız, bunun için ödeme yapmaya istekli misiniz? Yorum alanına bir mesaj bırakın!