In today’s competitive food, personal care, and e-commerce industries, selecting the right flexible packaging material solutions directly impacts product quality, cost efficiency, shelf life, and brand image.

Como profissional flexible packaging manufacturer in China, Embalagens Huiyang provides insight into how each packaging material performs in terms of protection, visual appeal, and application suitability.

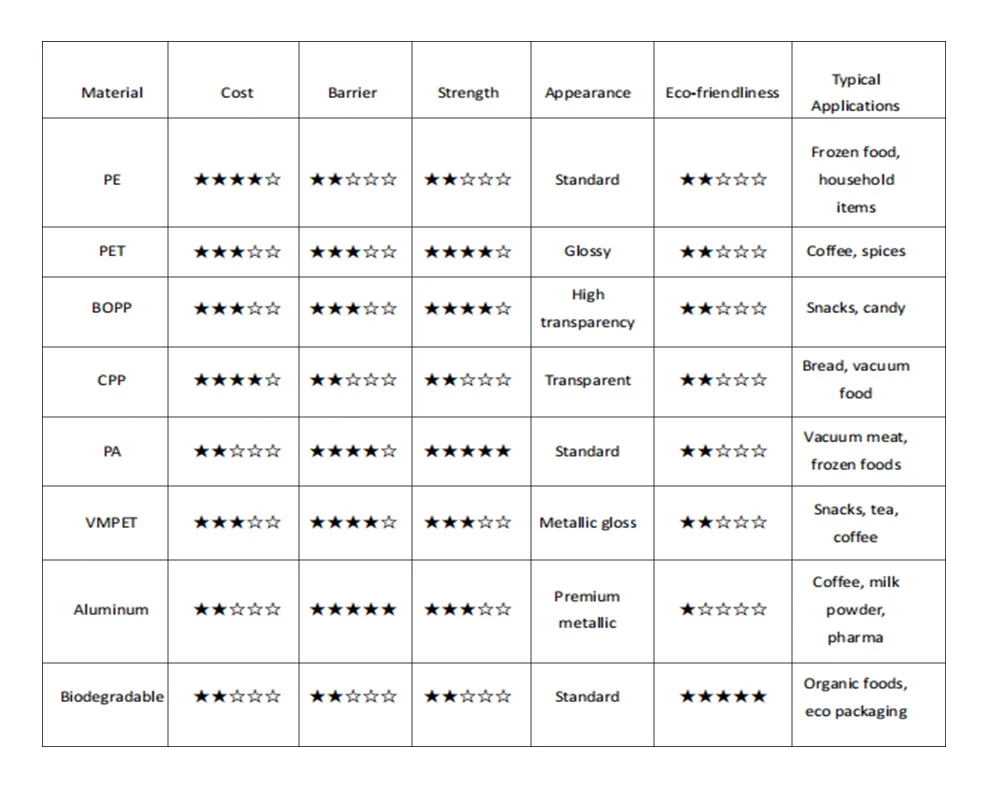

This guide compares the most common flexible packaging materials — PE, PET, BOPP, CPP, PA, VMPET, aluminum foil, and biodegradable films — helping you find the best solution for your packaging needs.

1. PE Packaging (Polyethylene)

PE bags are one of the most widely used flexible packaging materials due to their cost-effectiveness and versatility.

Key Features

- Soft texture with good transparency

- Non-toxic and food-safe

- Excellent sealing properties

Vantagens

- Affordable and easy to process

- Flexible and crack-resistant even at low temperatures

- Ideal for automated production lines

- Safe for direct food contact

Desvantagens

- Limited barrier protection against oxygen and odor

- Prone to puncture

- Simple appearance

Typical Applications

- Frozen food bags

- Bread, snack, and candy packaging

- Refill pouches for daily products

2. PET Packaging (Polyester)

PET film is widely used as a structural layer in flexible packaging material solutions because of its high strength and visual appeal.

Vantagens

- Excellent mechanical strength and tear resistance

- High heat and cold resistance

- Superior printability for premium designs

- Often laminated with PE or aluminum foil for barrier enhancement

Desvantagens

- Higher material cost

- Requires lamination for full barrier properties

Aplicações

- Coffee and tea packaging

- Seasoning and dry food pouches

- Vacuum packaging for premium snacks

3. BOPP Packaging (Biaxially Oriented Polypropylene)

BOPP films are commonly used by flexible packaging manufacturers as the outer layer for laminated films.

Vantagens

- High clarity and gloss

- Excellent stiffness and print quality

- Good moisture resistance

Desvantagens

- Limited gas barrier

- Low heat resistance

- Not suitable for sharp or heavy products when used alone

Aplicações

- Snack and candy packaging

- Outer film layer for laminations

- Printed food wraps

4. CPP Packaging (Cast Polypropylene)

Embalagens Huiyang, as an experienced flexible packaging manufacturer, often recommends CPP as a sealing or inner layer material.

Vantagens

- Soft, transparent, and heat-sealable

- Food-safe and odorless

- Cost-effective substitute for PE in multilayer structures

Desvantagens

- Moderate strength

- Average heat resistance

- Needs lamination for barrier improvement

Aplicações

- Bread and bakery bags

- Inner layer for food packaging

- Vacuum packaging with PA

5. PA Packaging (Polyamide/Nylon)

PA offers superior toughness and puncture resistance, often laminated with PE or CPP in flexible packaging material solutions.

Vantagens

- Excellent oxygen barrier

- High puncture resistance

- Performs well at low temperatures

- Great transparency

Desvantagens

- Moisture absorption may affect stability

- Higher production cost

Aplicações

- Vacuum-packed meat and seafood

- Frozen food bags

- Pharmaceutical packaging

6. VMPET Packaging (Vacuum Metallized PET)

VMPET combines PET’s strength with enhanced barrier performance, making it one of the most popular options among flexible packaging manufacturers.

Vantagens

- Strong protection from light, oxygen, and moisture

- Metallic gloss for premium product appearance

- Lightweight and flexible

- Lower cost than pure aluminum foil

Desvantagens

- Slightly weaker barrier than aluminum foil

- Sensitive to folding or poor lamination

Aplicações

- Chips and snack packaging

- Coffee and tea pouches

- Dry food and spice packaging

7. Aluminum Foil Packaging

When maximum protection is required, Embalagens Huiyang offers flexible packaging material solutions that include aluminum foil layers.

Vantagens

- Exceptional barrier against oxygen, moisture, and light

- Extends product shelf life

- Luxurious metallic finish for premium products

Desvantagens

- Custo elevado

- Easily creased

- Difficult to recycle

Aplicações

- Coffee beans and powdered milk

- Nutritional and pharmaceutical packaging

8. Biodegradable Packaging Materials (PLA, PBS, etc.)

As an eco-conscious flexible packaging manufacturer, Embalagens Huiyang promotes biodegradable film options that meet EU and North American environmental standards.

Vantagens

- Made from renewable plant-based sources

- Environmentally friendly and sustainable

- Enhances brand image among eco-minded consumers

Desvantagens

- Higher cost than conventional plastics

- Lower barrier and heat resistance

- Limited market maturity

Aplicações

- Organic food packaging

- Eco-friendly e-commerce mailers

- Export products

Why Choose Huiyang Packaging for Your Flexible Packaging Material Solutions?

With over a decade of experience, Embalagens Huiyang delivers custom flexible packaging material solutions for food, beverages, personal care, and industrial applications.

We provide full-service OEM & ODM capabilities, including material selection, printing design, and lamination structure optimization to ensure your products achieve both functionality and shelf appeal.

Se precisa de PE, PET, BOPP, CPP, PA, VMPET, aluminum foil, or biodegradable packaging, our team helps you find the most cost-effective and sustainable solution.

Choosing the Right Material

Low cost, high volume → PE, CPP

High strength and visual appeal → PET, BOPP

Vacuum and puncture resistance → PA

Mid-high barrier performance → VMPET

High-end shelf life → Aluminum foil

Eco-friendly and export markets → Biodegradable materials

Tip: Laminated packaging (e.g., PET/BOPP + VMPET + PE or PA + PE) often balances barrier, cost, and appearance perfectly.

Conclusão

Packaging is more than just protection; it’s a silent marketer for your brand. Choosing the right flexible packaging material ensures product quality, shelf life, and market competitiveness.

Contact us today for professional guidance on selecting flexible packaging materials, along with free samples for testing.