恵陽包装, 私たちは、国際的なペットフードブランドのOEM生産の最前線で何年も過ごし、何万ものペットフードを扱ってきました。 高温レトルトバッグ 毎日。121℃殺菌でアルミ箔のパウチが破裂したり、環境に優しい素材が不採用になったり、やり直しになったり。これらは教科書的な理論ではなく、製造現場から得た教訓なのです。. カスタムレトルトパウチメーカーとして, 当社は、耐熱性、コスト効率、製品の安全性のバランスが重要であることを熟知しています。当社の経験により、信頼性が高く、生産に適したパッケージングを毎回お届けすることができます。.

高温レトルト袋の「地獄テスト」:121℃に耐えられる素材とは?

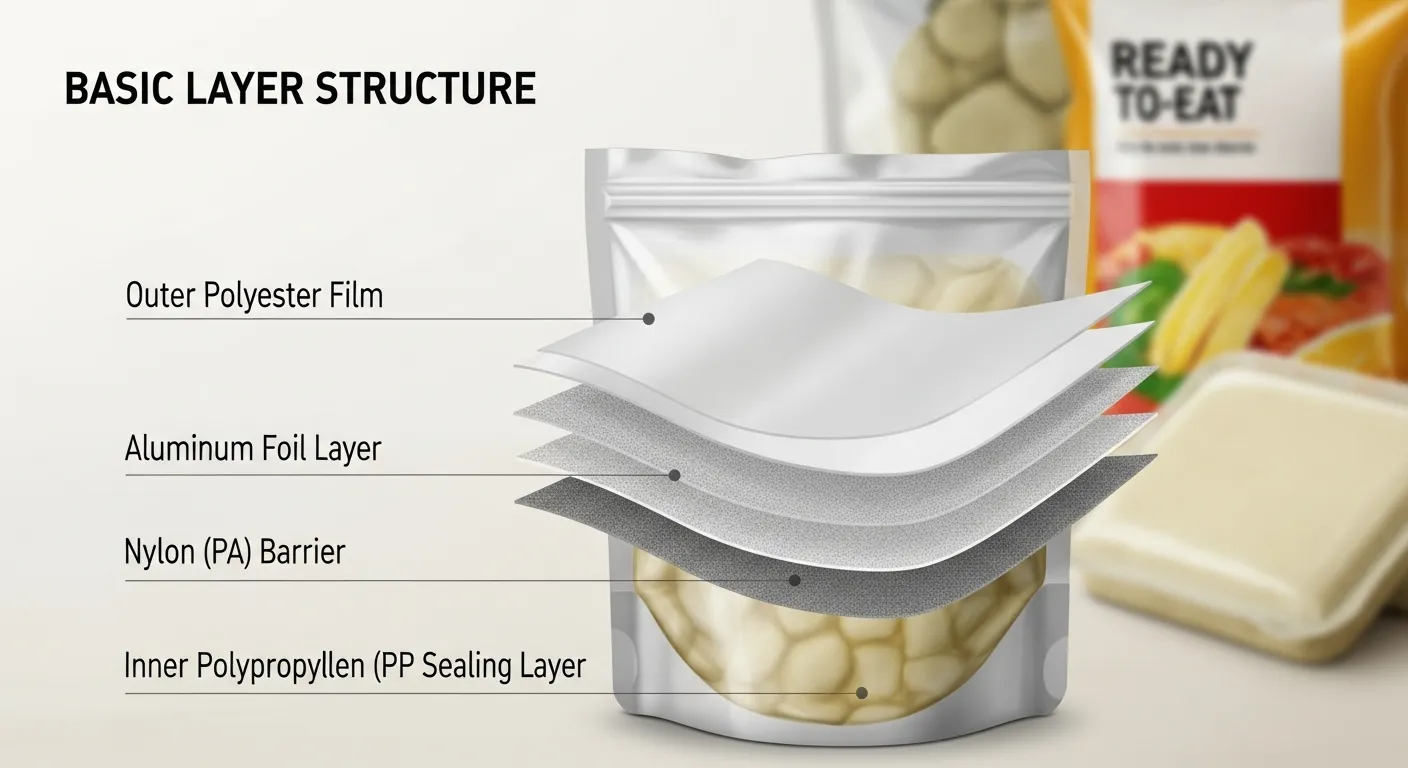

基本4層構造(業界標準)

インスタントカレーの袋を開けると、この「重ね爪の流れ」が見える:

外層12μmPETフィルム

- 機能:傷がつきにくく、穴が開きにくい。.

- 秘密:あるブランドは経費節減のためにBOPPに切り替えたが、レトルト処理後に印刷模様が抽象画のようになってしまい、80万元の損失を出したことがある。.

セカンドレイヤー15μmナイロン(PA)

- 機能:耐衝撃性+酸素透過防止、包装の「靭帯」に相当。.

- 横転事件:某OEM工場が未延伸PAを誤って使用し、121℃調理後の収縮率が5%を超え、袋がザワークラウト状にシワシワになった。.

コア:7μmアルミ箔

- 機能:酸素、光、水蒸気を遮断し、生命を守る核となる。.

- 苦労した点アルミニウム層のピンホール率が3/㎡以下であること(試験時に高電圧の電気火花を使用し、穴があると青色光を発する)。.

インナーレイヤー70μm CPP(キャストポリプロピレン)

- 機能:食品と直接接触するため、ヒートシール性を最大限に高める必要がある。.

- 血と涙の歴史:CPPのロットの耐熱性が不十分で、調理後に袋がビニール臭くなる。リコール費用はスイートルームが買えるほど。.

上級選手

- アルミホイルなしアルミ箔の代わりにEVOH(エチレン・ビニルアルコール共重合体)を使用し、酸素透過度は3cc/㎡・day以下。日本のニチレイの低温調理袋はこのトリックを使っているが、コストはアルミ箔より40%高い。.

- 富裕層専用:航空宇宙グレードの酸化ケイ素(SiOx)フィルムで、耐熱温度150℃、電子レンジ対応。アメリカのレトルトパウチ(高温レトルトスタンドアップバッグ)ブランドPackitはこれで軍からの受注を獲得したが、1平方メートルあたりの価格はステーキ2ポンドが買えるほどだ。.

2.致命的な詳細レトルト袋の「100℃温度差死活ライン

1.温度の裏切り者:ヒートシール

シール強度≧50N/15mmは業界のレッドラインである。しかし、ここには悪魔のようなディテールがある:

- コールドシールVSヒートシール:

コールドシール接着剤(日本の東洋製罐のトヨラックなど)は135℃で90%以上の強度保持率を持つが、生産ラインの速度は30%まで落とさなければならない。.

従来のヒートシール層(CPP)は低コストだが、温度差が少しでも大きいと剥離する可能性がある。ある鋳物工場では、蒸気圧が2psi変動しただけでバッチが剥離し、スクラップになったことがある。.

2.インビジブル・キラー:残留溶剤

印刷インキの残留溶剤は5mg/㎡以下でなければならない(国家標準GB 9685)。某ネット有名人漬け魚惣菜ブランドが覆された:

- 華やかな印刷を追求した結果、インキ層の厚みが基準を超えた→調理中に溶剤が蒸発して膨張→アルミ箔に微細孔が発生→賞味期間中の袋の膨張率が17%になった;;

- アフターセールスのコストは、新たな生産ラインを建設するのに十分で、血のにじむような損失だ!

3.「世代が強いる「需要

- 電子レンジ対応+透明:外層は140℃の耐熱性と透明性が要求される。ドイツのKHS社はPET/PA/EVOH/PPの4層構造の透明調理袋を発売したが、酸素透過性がアルミ箔袋の10倍もあり、短棚商品としてしか使えない。.

- 環境保護の個性ヨーロッパのあるペットフード・ブランドは紙とアルミの複合袋を使用し、リサイクル可能だと主張している。リサイクル工場は直接、紙+アルミ+プラスチックの受け入れを拒否している。このグリーンウォッシュの波はうまく演じている。.

2025年のブレイクアウトゲームのルールを書き換えるのは誰か?

1.政策核爆弾:アルミホイルの世界的包囲

- EUは2025年から、アルミニウムを含む複合包装材に1トン当たり800ユーロのエコロジー税を課す。.

- 日本包装協会は、アルミ箔の一部をアルミ蒸着PET(VMPET)で代替する「ハーフアルミ化計画」を強力に推進しているが、酸素バリア性が30%低下し、賞味期限の短縮を余儀なくされる。.

2.素材革命:ナノコーティングの逆襲

- セラミックコーティング:日本の大塚包装のAlOxコーティング(酸化アルミニウム)は、150℃の耐熱性があり、電子レンジで温めることができる;;

- グラフェン補強層:中国の研究機関が耐パンク性能を200%向上させたサンプルを試作したが、1トンあたりのコストはBYDが買えるほど。.

3.プロセスブラック技術:8時間から8分へ

- 超高温瞬間殺菌(UHT):135℃/3秒瞬間殺菌、ハイバリアアルミメッキ袋使用、賞味期限は18ヶ月から6ヶ月に延びるが、風味損失率は5%以下(従来の蒸しロスは15%);;

- レーザーシール:ヒートシールストリップに代わるもので、精度±0.1mm、特殊形状の袋(自立ノズル袋など)に適しているが、設備投資は小都市の家が買えるほど。.

メーカーのためのサバイバルガイド

- 低価格ボリュームタイプ4層アルミ箔袋+従来の蒸し工程で、県内市場を中心に展開;;

- ミッドエンド・アップグレード:VMPETは50%アルミホイル+UHT殺菌に取って代わる;;

- 高級プレミアムタイプアルミフリーEVOH透明袋+レーザーシール+カーボンフットプリントラベル。.

(市場ポジショニング、サイズ、数量をお聞かせください。)

蒸し袋の中の業界を見通す

コンビニエンスストアでインスタントカレーの袋を手に取ったとき、あなたが目にするパッケージの価格の差は、材料科学者、政策立案者、原価計算担当者の10年にわたる闘いの背後にある。今度袋を破るときは、考えてみてほしい。このフィルムがあなたの口に安全に食事を届けるまでに、どれだけの生と死の度合いを耐えてきたかを。.

相互作用環境に配慮した包装は食品価格を30%上昇させるが、1ヶ月あたり3平方メートルの土地の汚染を減らすと知っていたら、あなたはそのためにお金を払う気がありますか?コメント欄にメッセージを残してください!