Unter Huiyang Verpackung, we help snack brands choose the right high-barrier structure for crispy, long-lasting freshness.

Let’s be honest — no one likes soggy chips.

If you’ve ever opened a bag and found the crunch gone, you already know how much the packaging matters.

The real secret behind that perfect crispy bite?

Barrier performance.

Snack makers often debate between aluminum foil und metallized film (VMPET). Both look similar on the outside, but they behave very differently when it comes to blocking moisture, oxygenund light.

Here’s what you should know before you choose.

1. The Films Doing the Heavy Lifting

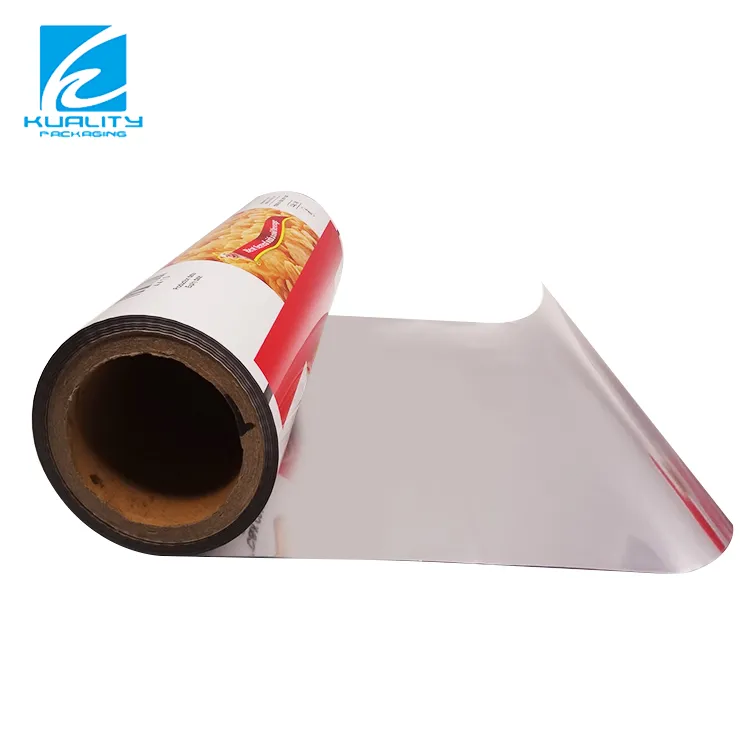

Most chip bags aren’t made from a single layer. They’re laminated films, each doing a specific job — one gives stiffness, another seals, and another blocks air.

Here are the main structures used in snack packaging:

| Structure | Eigenschaften | Typical Use |

|---|---|---|

| PET/AL/PE | Highest barrier against oxygen, moisture, and light. Slightly stiffer and heavier. | Premium chips, export markets, long shelf life. |

| PET/VMPET/PE | Great balance of barrier and cost. Lightweight and flexible. | Standard chips, regional brands. |

| PET/NY/PE | Strong puncture resistance and toughness. | Large packs, heavy-duty transport. |

| PET/PE | Basic structure, medium barrier. | Short shelf life or low-cost products. |

Quick takeaway:

- If your chips travel far or stay on shelves for months, choose PET/AL/PE.

- If you want protection + cost balance, PET/VMPET/PE is your best bet.

2. Why Barrier Performance Actually Matters

Air and humidity may not seem like much, but they can quietly ruin a good snack.

Once oxygen seeps through the film, oxidation begins — and that’s when chips lose flavor and texture.

Brands focus on three barrier indicators:

- Low OTR (Oxygen Transmission Rate) — keeps oil fresh

- Low WVTR (Water Vapor Transmission Rate) — prevents sogginess

- Light protection — reduces UV damage and flavor fading

Aluminum foil gives the strongest shield — practically zero transmission.

But modern metallized films are getting close. They’re lighter, more cost-effective, and easier to seal on fast production lines.

For many brands, the difference in barrier is small — but the difference in efficiency and cost can be huge.

Here in the middle section, Huiyang Verpackung works closely with snack factories to test and select the best film for expected shelf life and distribution conditions.

3. How We Keep the Quality in Check

In packaging, what you can’t see often matters most.

That’s why every batch we produce goes through strict testing:

- Seal strength — ensures bags won’t burst

- Leak detection — finds even micro pinholes

- Puncture & tear resistance — protects during handling

- Visual checks — no color drift or print defects

Each roll is also tested for OTR and WVTR, ensuring barrier performance meets specifications.

Our rule is simple: if it doesn’t pass, it doesn’t ship.

4. What Makes Our Films Different

We’ve been producing gravure-printed, high-barrier snack films for years, and one thing is clear — every brand needs a slightly different solution.

Some choose aluminum foil for maximum protection; others prefer metallized film for flexibility and cost savings.

We help you pick the structure that matches your shelf-life goals and market positioning.

Here’s why brands choose us:

- Tailored structures – PET/AL/PE, PET/VMPET/PE, PET/NY/PE, or any custom mix

- Beautiful gravure printing – sharp details, rich colors, metallic effects

- Strong lamination & sealing – keeps chips safe and leak-free

- Eco-friendly options – recyclable PE, bio-based materials

We don’t just sell film — we help brands build packaging that performs and sells.

Abschließende Überlegungen

Choosing between aluminum foil and metallized film isn’t about appearance — it’s about how you want your chips to behave on the shelf and in the hands of your customer.

If you want to test which structure suits your chips best, Huiyang Verpackung is here to help.

Let’s talk about your shelf-life goals, your market, and your production line, and find the best high-barrier packaging solution.