The short answer is definitely. A fruit puree pouch can preserve nutritional value and be a safe, healthy product format, but only when formulation, processing, and packaging are engineered and validated together. From a packaging buyer’s perspective, the pouch is an enabling technology: it either protects nutrients or accelerates their loss.

Huiyang, a leading custom flexible packaging manufacturer, brings a practical, industry-focused guide that explains what fruit puree is, which nutrients are fragile, how a fruit puree pouch must be specified, how filling methods affect health attributes, and which tests and documentation buyers should require.

What Is Fruit Puree — and What Matters Nutritionally?

A fruit puree is a homogenized fruit mash (single-fruit or blended), characterized by specific Brix (solids), pH levels, and Bostwick consistency. Key nutrition points for puree-based SKUs:

- Primary nutrients: vitamin C, provitamin A (carotenoids), polyphenols, some soluble fiber, and natural sugars.

- Labile components: vitamin C, certain polyphenols, and volatile aroma compounds are sensitive to oxygen, light, and heat.

- Physical form: particle size and viscosity affect mouthfeel, dosing, and spout selection.

For brands, the goal is to deliver the declared nutrient profile at the point of consumption — not just at fill. That requirement makes packaging choices technical and measurable.

Packaging Objectives for a Protective Fruit Puree Pouch

A properly specified fruit puree pouch must meet these preservation objectives:

- Limit oxygen ingress (low OTR) to reduce oxidation of vitamin C and aromas.

- Block light (low % transmission) when pigments or vitamins are photosensitive.

- Control moisture exchange (low MVTR) to avoid texture changes.

- Ensure seal/spout integrity to prevent contamination and recontamination after opening.

- Be compatible with the chosen thermal process (hot-fill, aseptic, retort) without delamination or migration.

Set targets in technical terms — e.g., target OTR < X cc/m²·day and MVTR < Y g/m²·day for the intended shelf life and distribution profile.

Recommended Fruit Puree Pouch Structures

Choose laminate families according to shelf-life and distribution:

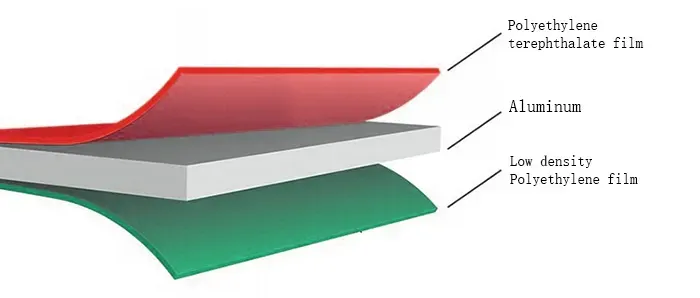

- High-barrier, opaque (long ambient shelf life)

- Typical structure: PET/AL/PE (foil laminate). Use when maximum light and oxygen barrier is required (export, long shelf life).

- Best for: shelf-stable purees, infant/child products with long transit.

- High-barrier, semi-transparent (balance barrier + visibility)

- Typical structure: PET/EVOH/PE or PET/SiOx/PE. EVOH provides low OTR while allowing some clarity.

- Best for: ambient purees where the brand needs partial visibility and a 6–8 months shelf life.

- Mechanical robustness (frozen/chilled or rough logistics)

- Typical structure: PA/PE or PET/NY/AL/PE with nylon for puncture resistance.

- Best for: frozen purees, long-distance refrigerated distribution.

- Sustainability-focused options

- Mono-material (PE/PE or PP/PP) with thicker gauge and possibly oxygen absorbers for shorter ambient shelf life. Use when recyclability is a strong commercial requirement and distribution is local/short.

For spout pouches, specify spout body material (PP for hot-fill/sterilization, PE for ambient), spout diameter compatible with particulates, and tamper-evident closure where relevant.

How Filling and Processing Affect Nutritional Outcomes

Processing choices for fruit puree pouches have a major impact on labile nutrients:

- Hot-fill (70–95°C): reliable microbial control; causes some nutrient loss (notably vitamin C). Works with PET/EVOH/PE or foil laminates, often acceptable when validated. Pay attention to the heat resistance level of the PE. Ordinary LDPE (low-density polyethylene) will undergo severe softening above 90 ° C, causing deformation or leakage at the sealing point during high-pressure filling.

- Pasteurization / mild thermal hold: gentler nutrient loss but requires cold chain or higher-barrier pouches.

- Aseptic filling: sterilize product and pouch separately — best nutrient retention and long ambient shelf life without extensive heat exposure. Requires certified aseptic film and validated processes.

- Retort (sterilization at ~121°C): highest safety margin for shelf-stable products but greatest nutrient degradation; used only when necessary.

Additional process controls that protect nutrition:

- Headspace inerting (N₂ blanketing) before sealing to reduce dissolved/initial oxygen.

- Minimized residence time at high temperature and rapid cooling to preserve volatiles.

- Particle management to avoid entrapped air pockets that accelerate oxidation.

Piloting on the brand’s actual filler is essential; lab data alone is insufficient.

Compliance, Testing, and Documentation

A packaging buyer must require specific documentation and test results before approving a fruit puree pouch:

- Material spec and Declaration of Compliance (DoC), such as FDA or EC 10/2011, for all film layers, inks, adhesives, and spout materials.

- Migration testing (overall and specific migration) and organoleptic (odor/taste) assessments on finished laminates after intended processing and storage.

- OTR/MVTR reports for target lifetime and environmental conditions.

- Seal strength, burst, and leak testing with spout installed.

- Filling-process validation reports (hot-fill, aseptic, retort) and pilot-run sign-offs on the brand’s line.

- Shelf-life validation (accelerated and real-time) reporting nutrient retention (e.g., % vitamin C), color ΔE, headspace O₂, and microbial stability.

- Traceability and QC plan for film lots, spout lots, and finished goods.

Insist on acceptance criteria (e.g., minimum % vitamin C retained at X months) and contractual liability for shelf-life claims.

Trade-offs and Commercial Considerations

Packaging selection is a set of trade-offs:

- Barrier vs recyclability: foil/EVOH gives the best protection but complicates recycling. Mono-materials improve circularity but often reduce ambient shelf life or require absorbers.

- Cost vs shelf life: higher-barrier laminates and aseptic lines increase unit cost but reduce waste and claims. Run total-cost comparisons, including returns and waste.

- Convenience vs nutrition: resealable spouts increase convenience but may introduce recontamination risks if hygiene and spout design are not managed. Tamper-evident and anti-choke measures should be taken into consideration as well.

Position the pouch solution based on channel, geography, and brand claims (e.g., premium, organic, export).

Actionable Buyer Checklist

Before committing to a volume run, secure:

- Target OTR/MVTR and chosen laminate spec.

- Spout material, diameter, and DoC.

- Pilot-run on intended filler with leak/seal tests.

- Migration, organoleptic, and shelf-life reports, including nutrient retention.

- Filling validation (hot-fill/aseptic/retort) and headspace management plan.

- QC & traceability plan and agreed acceptance criteria.

الخاتمة

From a B2B packaging perspective, a fruit puree pouch is a healthy format only when its laminate architecture, spout system, and filling process are selected and validated to protect the product’s sensitive nutrients across the intended distribution. The pouch format is not a health guarantee — it is an engineering tool. Brands and procurement teams should treat pouch specification as a product development task: set measurable preservation targets, require pilot validation, and document acceptance criteria before scaling. When done right, the fruit puree pouch delivers convenience, safety, and nutritional value — and that is what makes it a durable format for modern food brands.

About Huiyangg

Huiyang Packaging is a leading custom flexible packaging manufacturer with over 25 years of experience serving global brands in food, daily goods, and film solutions.

We combine advanced technology with sustainable design to provide wholesale food packaging bags, daily chemical bags, and films that protect product freshness and enhance shelf appeal.

Our production follows strict quality management systems, and we support one-stop custom fruit puree pouch solutions from design through delivery, helping clients get reliable, market-ready packaging while building long-term partnerships.